What is control cables?

In a large factory, various machinery and equipment operate in an orderly manner, following the command of the central control system, and the "bridge" connecting these devices with the control system is the control cable. Control cable is an insulated cable specifically used for transmitting control signals, mainly applied in industrial automation, power systems, transportation and other fields, to achieve remote control, monitoring and protection functions of equipment.

Control cables are suitable for industrial and mining enterprises, energy and transportation departments, etc., and are used for controlling and protecting circuits with AC rated voltage below 450/750 volts. Common specifications include 300/500V. Although it does not transmit powerful electrical energy, it carries various key control commands and feedback signals to ensure that the equipment operates according to the predetermined program.

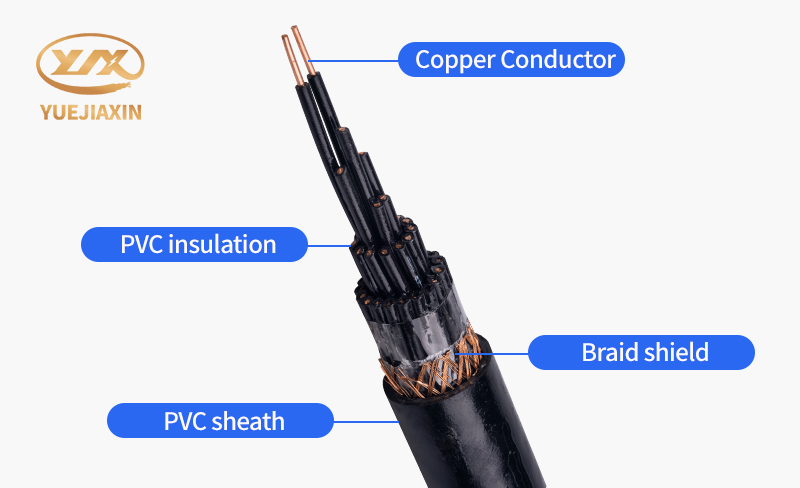

Control cables have a different 'mission' from the commonly used power cables. Power cables are mainly responsible for transmitting powerful electrical energy, just like the arteries of the human body, providing power sources for various large equipment, while control cables focus on transmitting control signals and operation instructions, serving as the "nervous system" of equipment, used to achieve precise control and monitoring of electrical equipment. Structurally, control cables have distinct characteristics. It has a large number of cores, commonly ranging from 2-61 cores, which is like an integrated "signal channel" that can simultaneously transmit multiple different control signals or monitoring data. The cross-sectional area of each wire core is relatively small, usually between 0.75-6 square meters, because it transmits low current and low voltage signals, and does not need to carry large currents like power cables. The smaller cross-sectional area is sufficient to meet signal transmission needs, save costs, reduce cable volume and weight, and facilitate laying and installation. Control cables have multiple excellent performance advantages, enabling them to work stably in various complex environments. Anti interference capability is also a major highlight of control cables. By using shielding layers, special insulation materials, and reasonable wire core twisting methods, control cables can effectively block the intrusion of external electromagnetic interference, prevent internal signal leakage, and ensure the accuracy and stability of signal transmission. In addition, control cables also have high durability and flexibility. It can maintain stable performance in long-term continuous operation, reduce maintenance and replacement frequency, and lower operating costs. Moreover, it has good flexibility, making it easy to bend and lay, and can adapt to various complex wiring environments. Whether it is a small cable tray or a device that requires frequent movement for connection, the control cable can easily handle it.

Control cables are ubiquitous in various fields and play an indispensable role in our lives and production. Faced with the dazzling array of control cable products on the market, how to choose high-quality products has become the key.

Control cables, this seemingly insignificant yet crucial 'behind the scenes hero', silently support the normal operation of various fields and are an indispensable key component in modern industry and infrastructure construction. From power transmission to communication data, from mechanical equipment to building facilities, its presence is everywhere, bringing convenience and security to our lives and production. When selecting control cables, we must consider various factors comprehensively and choose the appropriate product to ensure that it can perform at its best in practical applications. Meanwhile, proper use and maintenance can also extend the service life of control cables and reduce the probability of faults occurring.