Small cables, big lessons

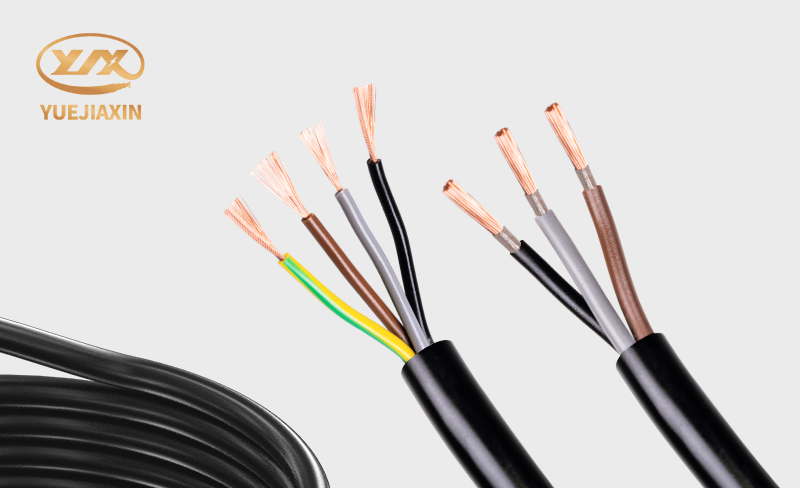

In daily life, cables are everywhere but often overlooked by us. The cable family is huge and has many members. Different types of cables have significant differences in function, structure and use. Power cables are mainly responsible for transmitting and distributing high-power electrical energy in the main lines of the power system. Power cables are like the "aorta" of the city, ensuring the power supply of the entire city. The structure of power cables is relatively complex, usually consisting of four parts: core (conductor), insulation layer, shielding layer and protective layer. The wire core is the core of the conductor, which is generally made of copper or aluminum and other metal materials with good conductivity. Its cross-sectional area depends on the power to be transmitted, ranging from a few square millimeters to thousands of square millimeters. The insulation layer plays the role of isolating the wire core from the earth and the wire cores of different phases to ensure the safe transmission of electric energy. Common insulating materials include cross-linked polyethylene and polyvinyl chloride. The shielding layer can limit the electric field inside the cable, protect personal safety and prevent external electrical interference. The protective layer can protect the cable from the invasion of external impurities and moisture, and prevent direct damage to the cable by external forces. Control cables are mainly used in industrial and mining enterprises, energy and transportation departments, etc., responsible for transmitting various control signals to achieve precise control of equipment. Compared with power cables, control cables usually have smaller conductor cross-sections. The color of its insulating core is generally black with white characters, which is easy to distinguish and identify. Communication cables are the bridge of the information age, used to transmit various communication signals such as telephone, television, and data. It allows us to talk to relatives and friends far away, watch TV programs from all over the world, and quickly browse Internet information.

The cable model is like their "identity card", and each letter and number contains specific information. With this information, we can easily understand the basic structure, performance characteristics and applicable scenarios of the cable.

The most common BV wire is the "star product" among home wires. BV is actually the abbreviation of "copper core polyvinyl chloride insulated cloth wire". The "B" here stands for cloth wire, which is mainly used for fixed laying, and the "V" means that the insulation layer is made of polyvinyl chloride (PVC). This material has good insulation performance and corrosion resistance, and the price is relatively affordable. Therefore, it is widely used in the wiring of low-voltage electrical equipment such as home lighting and sockets. If you see ZR-BV, it means that this is a flame-retardant BV wire. Flame retardants are added to the insulation material. When encountering open flames, it will not continue to burn after leaving the fire source. It can improve the safety of electricity use to a certain extent. It is often used in crowded places or buildings with high fire protection requirements. There is also NH-BV, which is a fire-resistant wire. When a fire occurs, ordinary wires may be burned quickly and stop working, but NH-BV wires can maintain normal power supply for a certain period of time, buying precious time for personnel evacuation and fire rescue. Let's take a look at the YJV model commonly used in power cables. "YJ" stands for cross-linked polyethylene insulation, and "V" stands for polyvinyl chloride sheath. Cross-linked polyethylene insulation material has excellent thermal-mechanical properties, electrical properties and chemical corrosion resistance, which enables YJV cables to withstand high temperatures and large current loads. They are often used in medium and low voltage power transmission in urban power grids, industrial and mining enterprises, etc. For example, the YJV22 cable, the "22" at the end indicates steel belt armor. This cable has stronger mechanical protection performance, is suitable for direct burial laying, and can withstand certain external force extrusion. If it is a YJLV model, "L" means aluminum core. Compared with copper core cables, aluminum core cables are lighter and cheaper, but their conductivity is slightly inferior. They are suitable for occasions that are more cost-sensitive and do not require particularly high conductivity, such as power transmission in some remote areas.

First of all, the cable specification determines the current carrying capacity of the cable. The larger the cross-sectional area, the greater the current it can carry. When selecting the cable cross-sectional area, it should be determined according to the actual load current size, and the laying length and laying method of the cable should also be considered. Because the longer the cable, the greater the resistance and the greater the voltage drop; different laying methods have different effects on the heat dissipation conditions of the cable, which in turn affects the current carrying capacity of the cable. The use environment also has an important impact on the choice of cable. If it is used in a high temperature environment, it is necessary to choose a high temperature resistant cable to ensure the stability of power transmission.

Cables play a huge role in our lives. From daily electricity security to industrial power transmission to information transmission in the field of communications, they are everywhere and are an indispensable infrastructure in modern society. By understanding the types, models, selection methods, installation and laying techniques, and daily maintenance points of cables, we can not only better ensure the safety of electricity use at home and at work, but also make correct decisions when carrying out related engineering construction.