Selection Guide for PV Project "Lifeline": How High-Quality PV Cables Escort Efficient Power Generation?

Guided by the "dual carbon" goal, the solar industry, as a representative of green energy, is developing rapidly. While we focus on popular topics like the power generation and conversion efficiency of solar power plants, there is an important yet easily overlooked role – solar cables – silently playing a crucial role behind the scenes. Have you ever wondered how these seemingly ordinary cables ensure stable operation in complex solar systems? What unique "abilities" do they possess to adapt to various harsh environments?

Solar cables, also known as solar-specific cables, are cables used in solar photovoltaic power plant systems specifically for transmitting DC power in the circuit. They act like the "blood vessels" of the solar system, stably transmitting the DC power generated by the solar panels to inverters or other electrical equipment, realizing the conversion and utilization of solar energy into electrical energy. Although cables are only a "small player" in the entire photovoltaic system, they are indispensable; without them, solar energy cannot be converted into the electricity we use daily.

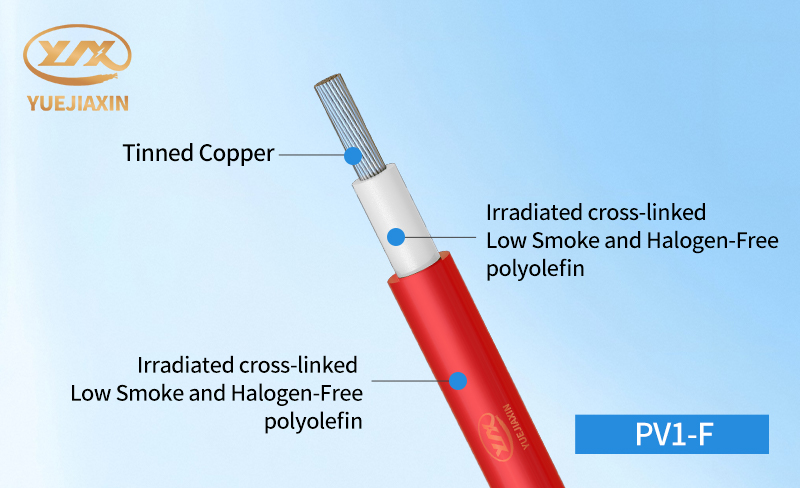

Don't be fooled by the ordinary appearance of solar cables; their internal structure is quite complex. From the inside out, they mainly consist of three parts: a conductor, an insulation layer, and a sheath. The conductor is the core of the cable, much like the main road of a highway, bearing the heavy responsibility of transmitting electrical energy. Solar cables typically use high-purity copper or tin-plated copper as the conductor material. These materials have strong conductivity, minimizing energy loss during transmission and ensuring efficient power delivery. The insulation layer acts like a "protective suit" for the conductor, located between the conductor and the sheath, primarily serving to isolate current and prevent leakage. It is generally made of special polyolefin materials, possessing not only excellent insulation and voltage resistance, able to withstand certain voltages without breakdown, but also excellent high-temperature resistance. The outermost sheath is the cable's "armor," mainly responsible for protecting the cable's internal structure from external environmental factors. Sheath materials typically have properties such as UV resistance, corrosion resistance, and abrasion resistance. In outdoor environments, cables are subjected to long-term exposure to sunlight, wind, rain, and chemical corrosion. If the sheath lacks these properties, it is easily damaged, thus affecting the cable's lifespan and performance.

What are the characteristics of solar cables? First, weather resistance is crucial. Since solar cables are mostly installed outdoors, they face various complex climatic conditions. They must withstand long-term ultraviolet radiation, ozone corrosion, and drastic temperature changes. Thanks to special materials and processes, solar cables effectively resist ultraviolet radiation, ensuring long-term stable operation. Furthermore, they function normally in both extreme heat and cold, without performance degradation due to extreme temperature variations. Second, temperature resistance is essential. During operation, the cable generates heat due to current flow, and the ambient temperature also affects it. Solar cables possess excellent temperature resistance, maintaining stable performance over a wide temperature range. Generally, they can operate normally at temperatures from -40℃ to +90℃ or even higher. In high-temperature environments, the cable insulation material does not soften or deform, ensuring unaffected insulation performance. In low-temperature environments, the cable does not become brittle, maintaining good flexibility and mechanical strength, preventing damage due to excessively low temperatures and ensuring power transmission. During installation and maintenance, solar cables are subjected to various mechanical forces, such as pressure, bending, tension, and stretching. Therefore, solar cables need to possess sufficient mechanical strength to withstand these external forces without damage. Solar cables, processed with special techniques, have insulation and sheaths with high toughness and abrasion resistance, maintaining structural integrity under impact. For example, during cable laying, bending and stretching may be necessary. If the cable's mechanical strength is insufficient, problems such as insulation cracking and conductor breakage can easily occur. The high strength characteristics of solar cables effectively prevent these situations, ensuring cable lifespan and system reliability.

Solar cables, though seemingly ordinary, play an indispensable role in solar systems. They are the "unsung heroes" of the solar industry, carrying the mission of transmitting green energy and ensuring the stable operation of solar systems. When selecting solar cables, careful consideration is essential. From materials and specifications to certifications, every aspect is crucial, as it not only affects the power generation efficiency of the solar project but is also closely linked to the system's safety and lifespan.

Looking to the future, with the continuous advancement of photovoltaic technology and the increasing diversity of its applications, solar cables will develop towards higher performance, greater environmental friendliness, and greater intelligence. It is believed that with the joint efforts of all parties, solar cables will continue to innovate, injecting even stronger momentum into the vigorous development of the photovoltaic industry.