RVV multi-core cables empower security monitoring, providing stable signals and anti-interference.

In the electrical field, you're probably familiar with the RVV multi-core flexible cable. Today, we'll unveil its mysteries. The three letters in the RVV designation have profound meanings. "R" stands for Flexible, like multiple strands of fine copper wire, allowing for easy bending and high flexibility. The first "V" is the polyvinyl chloride (PVC) insulation layer, which steadily controls the current within the conductor, ensuring electrical safety. The second "V" is also a PVC sheath layer, like a sturdy suit of armor for the cable. These three layers work together seamlessly, giving the RVV cable both the flexibility and resilience to withstand complex environments.

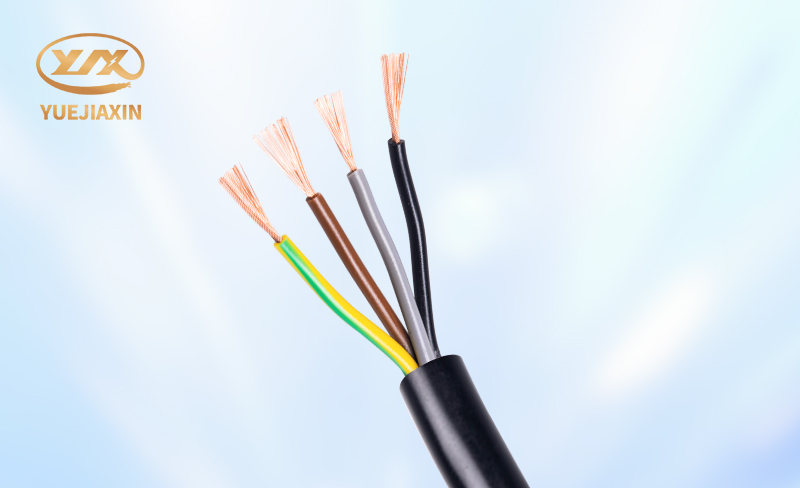

RVV cables feature conductors made of oxygen-free copper wire stranded together, boasting high purity and excellent conductivity. This significantly reduces resistance and power loss during transmission, resulting in energy savings and high efficiency. The multi-strand fine copper wire design provides exceptional flexibility, preventing easy breakage even with repeated bending, making it particularly suitable for applications requiring frequent cable movement and bending. Each core wire is individually wrapped with PVC insulation, preventing interference between cores and avoiding issues like signal crosstalk and short circuits, ensuring greater electrical safety. Furthermore, the PVC insulation material offers stable insulation performance and resistance to chemical corrosion, functioning reliably in humid environments or locations containing chemicals. The outermost PVC sheath tightly encases all insulated core wires, protecting them from external damage. To further enhance overall cable performance, filler material is added to the sheath layer. These design features allow the cable to easily withstand various conditions, ensuring stable line operation. RVV cables support flexible combinations from 2 to dozens of cores, with conductor cross-sectional areas ranging from 0.5mm² to 35mm², offering diverse specifications to meet the needs of various scenarios. Therefore, whether it's home decoration, industrial production, or security monitoring, you can find RVV cables of suitable specifications to meet diverse needs in one stop.

When selecting RVV cables, the first step is to determine the power and current load of the equipment, as this directly determines the number of cores and conductor cross-sectional area of the cable. Secondly, the operating environment must be considered, as different environments require different types of RVV cables. From the stable operation of household appliances to the efficient operation of industrial equipment, RVV multi-core flexible cables bridge the gap between power and signal transmission with their flexibility and reliability.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

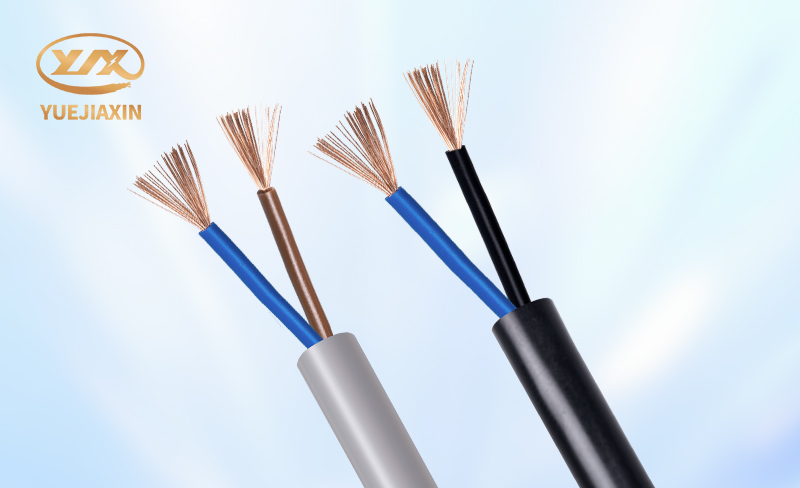

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable