Core Advantages and Cost-Effectiveness Analysis of Aluminum Alloy Cables

In our daily lives, we enjoy the convenience brought by electricity every moment. From being woken up by our phone alarms in the morning to the city lights shining brightly at night, electricity acts like an invisible bond, connecting every corner of our lives. And in this vast power transmission network, cables play a crucial role. Today, let's talk about a "star product" that is emerging in the power industry—aluminum alloy cables.

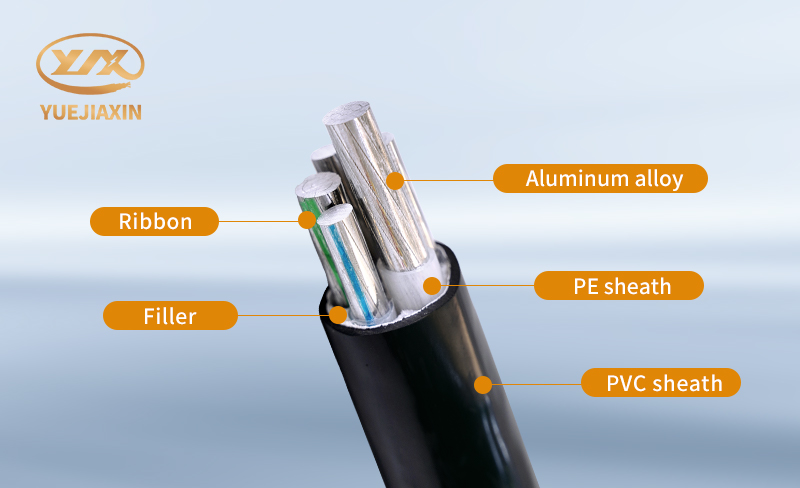

How are aluminum alloy cables different from the cables we commonly see? Aluminum alloy cables are not simply a mixture of aluminum and other metals. Instead, they are a new type of power cable created by carefully adding various alloying elements such as copper, iron, magnesium, silicon, zinc, and boron to pure aluminum, followed by special processing techniques and annealing treatment. This unique manufacturing method gives aluminum alloy cables many advantages that ordinary cables do not possess. The advantages of aluminum alloy cables are reflected in many aspects; whether it's performance, cost, or environmental friendliness, aluminum alloy cables demonstrate outstanding performance. During power transmission, cables are subjected to heat and pressure. Over time, the conductors of ordinary cables may experience "creep," leading to increased contact resistance, affecting power transmission efficiency, and in severe cases, potentially causing safety accidents. Aluminum alloy cables, through special alloy materials and annealing processes, significantly reduce the conductor's tendency to creep under heat and pressure. Compared to pure aluminum, its creep resistance is improved by 300%, ensuring the stability and reliability of the cable during long-term use.

While maintaining the same conductivity, aluminum alloy cables weigh approximately half that of copper cables, and cost only 30% to 50% of the price. This allows for a significant reduction in material procurement costs in large-scale power engineering projects. For projects with limited budgets, aluminum alloy cables are undoubtedly a highly cost-effective choice. Due to their light weight and good flexibility, aluminum alloy cables require relatively lower labor and equipment costs during installation. Furthermore, their small bending radius facilitates easier terminal connections, further shortening installation time and reducing costs. The surface of aluminum alloy cables is treated with anti-corrosion coatings, ensuring no release of harmful substances or heavy metal leakage during use, making them suitable for complex environments such as soil and dampness. In addition, for the same current carrying capacity, the line loss of aluminum alloy cables is similar to that of copper cables, but their lighter weight results in lower energy consumption during transportation and installation, indirectly reducing environmental impact.

Aluminum alloy cables, with their superior performance, significant cost advantages, and wide range of applications, are gradually changing our lives. With continuous technological innovation and growing market demand, the future of aluminum alloy cables is bright. They will evolve towards higher performance, greater environmental friendliness, and greater intelligence, providing our society with more efficient, reliable, and green power transmission solutions.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable