BV Single-strand or Multi-strand Cable for Home Wiring?

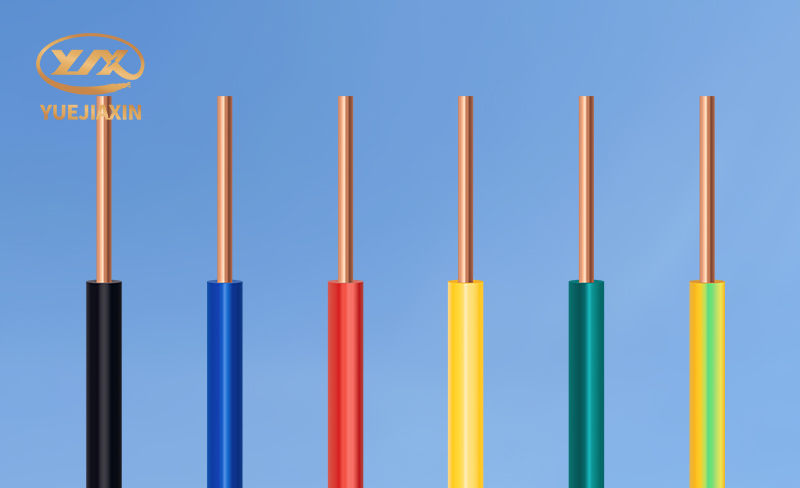

BV wires are ubiquitous in daily life, found in home renovations, office wiring connecting various appliances, and even in lighting systems in shopping malls. BV wire, short for copper core PVC insulated building wire, where "B" indicates building wire and "V" indicates PVC insulation. BV wires are suitable for power installations, household appliances, instruments, and telecommunications equipment with AC voltages of 450/750V and below. Most of the ordinary insulated wires and household wires we commonly use are BV wires, ensuring the normal operation of our lives and work. So what's the difference between single-strand and multi-strand BV wires? The cable source factory will now provide a detailed introduction.

A single-strand BV wire, also known as a solid wire, typically appears as a straight and relatively rigid line. Structurally, it consists of a solid copper conductor as its core, bearing the responsibility of conducting electricity. This copper conductor acts as the "spine" of the wire, providing a solid path for current transmission. Outside the copper conductor, a tightly wrapped insulation layer, typically made of polyvinyl chloride (PVC), acts like a protective armor, effectively isolating current and preventing leakage. It also provides flame retardancy, moisture resistance, and corrosion resistance, ensuring stable operation of the wire in various complex environments. In large-scale construction or wiring projects, the cost advantage of a single BV wire becomes apparent. The manufacturing cost of a single BV wire is relatively low, as is its maintenance cost. Due to its simple structure, the probability of failure is relatively small, and even if problems do occur, troubleshooting and repair are relatively convenient, further reducing long-term operating costs. The rigidity of a single BV wire provides better support and stability during installation, allowing installers to easily lay it along walls, floors, or cable trays without requiring excessive fixing measures.

Multi-strand BV wire, also known as flexible wire, differs from the rigidity of single-strand BV wire in its more flexible appearance. Its internal structure consists of multiple fine copper wires twisted together, working together to conduct electricity. This multi-strand structure gives the wire excellent flexibility, allowing it to be easily bent and wound. Like single-strand BV wire, these copper wires are also wrapped in an insulation layer made of polyvinyl chloride (PVC), providing reliable insulation protection and ensuring that the current is firmly confined within the copper wires for safe and stable transmission. The gaps between the multiple copper wires allow air to flow freely, effectively aiding in heat dissipation. In the operation of high-power equipment, wires generate significant heat; the excellent heat dissipation performance of multi-strand BV wire ensures stable operation even in high-temperature environments, reducing safety hazards caused by overheating. The twisted structure of the multiple fine copper wires allows for easy bending operations, making it suitable for navigating narrow cable trays or wiring within complex electrical equipment. In home renovation, multiple BV wires can be flexibly bent to perfectly fit various complex wiring routes, greatly improving the efficiency and aesthetics of wiring.

Single-strand BV wires and multi-strand BV wires are like two capable assistants, each with its own unique strengths. Single-strand BV wires, with their advantages of low cost, high stability, and ease of installation, are widely used in construction projects and industrial fixed equipment; while multi-strand BV wires, relying on their excellent flexibility, play an important role in complex home wiring, temporary power supply, and internal wiring of equipment with high requirements for wire bending.