Copper Core Cable vs. Aluminum Core Cable: A Comprehensive Comparison of Performance, Cost, and Lifespan

In modern society, electricity is like an "invisible partner" in our lives, from the first light we turn on when we wake up in the morning to the electronic devices that accompany us to sleep at night. It is everywhere, silently maintaining the normal functioning of our lives. In the vast network of power transmission, cables play a crucial role, serving as the "lifeline" for delivering electricity. There are many types of cables, among which copper-core and aluminum-core cables are the most common, playing a vital role in our lives and industrial production.

Conductivity is a key indicator of cable quality, directly affecting the efficiency and loss of power transmission. In terms of resistivity, under the same conditions, the resistance encountered by current when transmitted through copper-core cables is lower. Regarding line loss, aluminum-core cables have higher resistance, resulting in 30%-40% higher losses than copper-core cables, a difference that is particularly noticeable in high-load scenarios. In terms of conductivity, copper-core cables, with their lower resistivity, higher conductivity and current carrying capacity, and lower line loss, are undoubtedly the "king of efficiency."

The service life of power cables is a crucial factor that cannot be ignored, as it affects not only the stability of power supply but also subsequent maintenance costs and replacement expenses. In this regard, copper-core and aluminum-core cables exhibit significant differences due to their different material properties. Copper-core cables have strong oxidation resistance and stable chemical properties, allowing them to maintain good performance in various environments. Aluminum, on the other hand, is chemically reactive, and its surface easily forms a dense layer of aluminum oxide (Al₂O₃). While this oxide layer can protect the aluminum core from further oxidation to some extent, its melting point is as high as 2050℃, and its resistivity is extremely high, leading to increased contact resistance at the joints. During long-term operation, the joints are prone to loosening due to overheating, thus forming a vicious cycle of "oxidation - overheating - easier oxidation," severely affecting the cable's service life.

In terms of procurement costs, there is a direct and obvious difference between copper-core and aluminum-core cables, which is often the first factor many people consider when choosing cables. Due to the consistently high price of copper, copper-core cables have a relatively higher procurement cost. Aluminum-core cables, however, have found their niche in certain applications due to their cost and weight advantages. Temporary projects, such as construction sites and temporary exhibition venues, have relatively short power usage times and therefore lower requirements for cable service life. The affordability and ease of installation of aluminum-core cables make them an ideal choice for temporary power supply. On construction sites, aluminum-core cables can be easily moved and laid as construction progresses, and can be conveniently recycled after the project is completed, reducing costs. Furthermore, their lighter weight reduces the labor intensity for construction workers and improves construction efficiency.

In the world of power transmission, there is no absolute good or bad, only the most suitable choice. Whether it's to ensure a stable power supply for high-rise buildings or to reduce the cost of rural power grid upgrades, every cable selection carries the expectation of efficient and safe power transmission.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

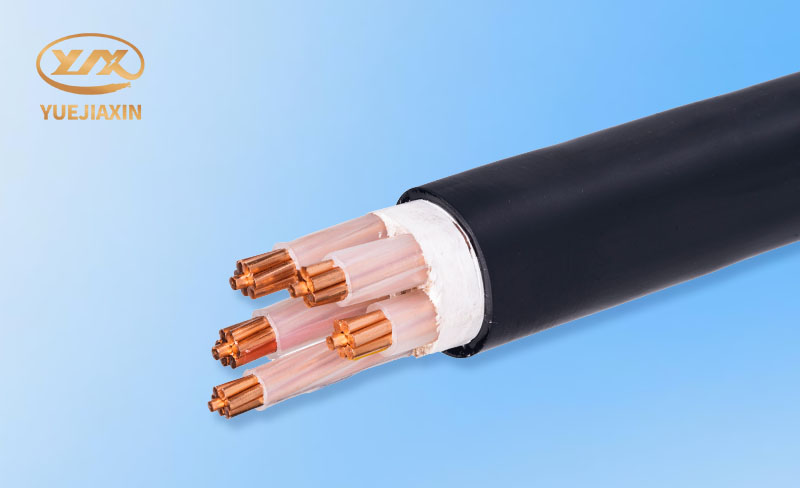

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable