What is a Multi-core Flexible Cable? Understanding its Structure, Advantages, and Application Scenarios

In our daily lives, electricity is ubiquitous, from the alarm clock that wakes us up in the morning to the lights that illuminate our rooms at night, from the mobile phones and computers we use every day to various large household appliances. Electricity acts like an invisible thread, connecting every moment of our lives. And within this vast power transmission network, there is a silently dedicated "behind-the-scenes hero"—multi-core flexible cables. Although they are not often noticed, they play an indispensable role in every corner of our lives.

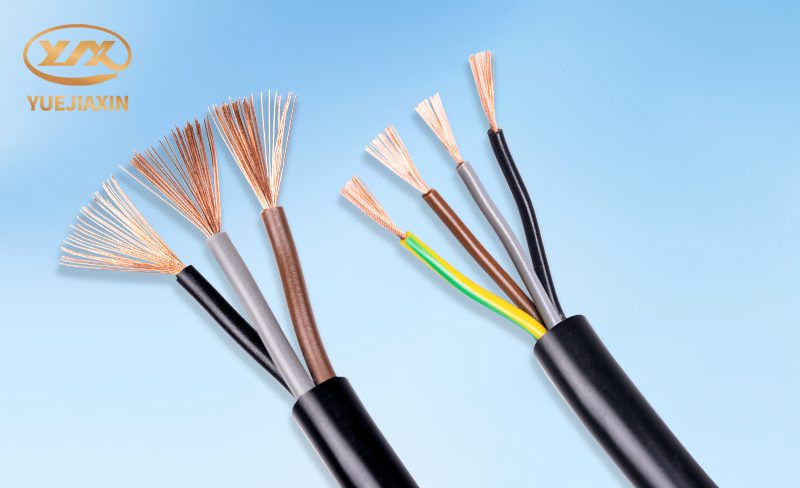

The structure of a multi-core flexible cable is like a meticulously constructed miniature world, with each part working closely together to ensure the cable's normal operation. It mainly consists of multiple conductors, insulation layers, fillers, and a sheath. The conductors are the core of the cable, like the blood vessels of the human body, responsible for transmitting electrical energy or signals. These conductors are usually made of high-purity metals such as copper or aluminum, because they have excellent conductivity, allowing current or signals to pass through smoothly. Furthermore, the conductors in multi-core flexible cables are often made of multiple strands of fine copper wire twisted together. This twisting method greatly enhances the cable's flexibility, allowing it to easily handle various complex wiring environments. The insulation layer is a crucial line of defense for electrical safety. The insulation layer is generally made of materials with excellent insulation properties, such as polyvinyl chloride (PVC) and cross-linked polyethylene (XLPE), which effectively prevent current leakage, avoiding electric shock accidents, and also prevent short circuits between different conductors, ensuring that each signal or current can be transmitted independently and stably. Multi-core cables are often filled with materials such as hemp rope and fiber materials. These fillers play a vital role. On the one hand, they enhance the compactness of the cable structure, allowing the various parts to be tightly integrated, making the entire cable more robust and durable; on the other hand, the fillers also improve the cable's tensile strength, reducing damage to the conductors when the cable is subjected to external pulling forces, extending the cable's service life. The sheath is the outermost protective armor of the cable, protecting the internal conductors, insulation layers, and fillers in all directions. The sheath is usually made of materials with good mechanical and environmental resistance properties, such as polyvinyl chloride and rubber. It can not only withstand external mechanical damage but also effectively prevent corrosion from chemical substances, and also has moisture-proof, waterproof, and UV-resistant functions, allowing the cable to work normally under various harsh environmental conditions, whether in damp basements, oily factory workshops, or outdoors exposed to sunlight.

Multi-core flexible cables play a crucial role in various aspects of our lives, thanks to their unique flexibility, excellent signal transmission stability, and strong durability. From the proper functioning of household appliances to the stable operation of security systems; from the efficient production of industrial equipment to the continuous power supply of communication devices, they are everywhere, silently safeguarding our lives and production processes.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable