Essential for Green Energy Track-Solar Cables

In today's era of rising green energy, solar power, with its clean and sustainable unique appeal, is gradually becoming a shining star on the energy stage. Whether it's the vast, sprawling solar power plants in the expansive deserts or the scattered distributed photovoltaic systems on city rooftops, solar energy is integrating into our lives in various ways, providing a continuous source of power for the sustainable development of our planet. Behind this green energy revolution, there is a silently dedicated yet crucial "behind-the-scenes hero"—solar cables. Like the blood vessels of the human body, they carry the vital task of transmitting solar energy, ensuring that every bit of clean energy reaches where it's needed. Let's now unveil its mysterious veil.

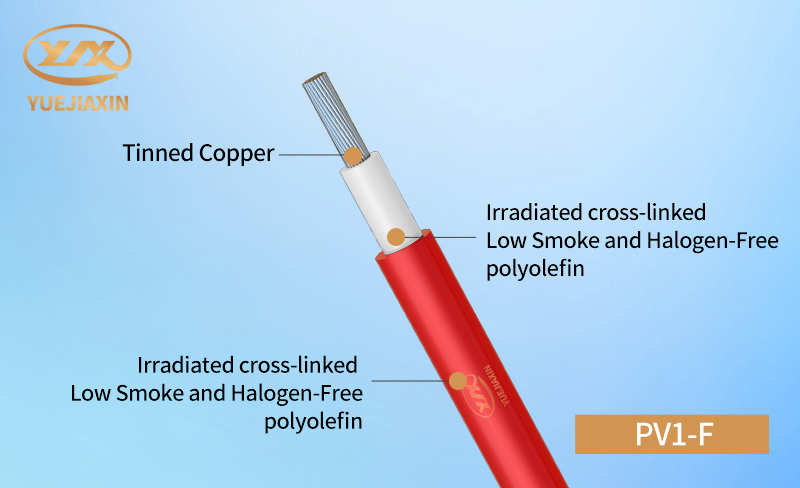

Solar cables, also known as solar cables, are cables specifically designed for solar photovoltaic power generation systems. They primarily connect solar panels, inverters, and other related equipment, efficiently and stably transmitting the direct current generated by the solar panels to the inverter, where it is converted into alternating current for use or fed into the power grid. While photovoltaic cables may not look significantly different from ordinary cables, their "internal" characteristics are vastly different. Ordinary cables are generally suitable for indoor, conventional environments with relatively low requirements for weather resistance and corrosion resistance; however, solar cables are often exposed to harsh outdoor environments such as direct sunlight, wind, rain, and extreme temperatures. Therefore, they have higher standards and requirements in terms of material selection and manufacturing processes.

Solar power plants are located in diverse and complex environments, facing various challenges such as high temperatures, humidity, acid and alkali corrosion, and strong ultraviolet radiation. In high-temperature environments, such as photovoltaic power plants in desert regions, where solar radiation is intense and temperatures are often very high, the cable insulation material should have good high-temperature resistance. Cross-linked polyethylene insulated cables are generally used, with a long-term allowable operating temperature of 90°C or even higher. In humid areas, such as power plants near the coast or rainforests, where air humidity is high and there may be seawater corrosion, the cables need excellent moisture resistance. The outer sheath usually uses waterproof and water-resistant materials, such as polyvinyl chloride sheathing.

Solar cables, as an indispensable key component in solar photovoltaic power generation systems, provide a solid guarantee for the efficient transmission of clean energy with their excellent performance and reliable quality. They are not only the bridge connecting photovoltaic modules and inverters, but also a crucial force driving energy transition and achieving sustainable development.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable