How much do you know about solar cable?

Solar cable, the full name is solar photovoltaic cable, in simple terms, it is the "blood vessel" responsible for transmitting electrical energy in the photovoltaic system. From the generation of direct current by photovoltaic panels to the transmission of electrical energy to inverters, junction boxes, and then to the power grid or energy storage equipment, solar cables participate in the entire process to ensure stable power transmission.

Solar cables are divided into DC and AC. DC solar cables are the "main force" in the photovoltaic system. They connect photovoltaic panels with inverters, junction boxes and other equipment, and transmit the DC power generated by photovoltaic panels. It must have excellent weather resistance, UV resistance, high temperature resistance, low temperature resistance and other properties, because it has to be "exposed" outdoors most of the time, and it must withstand wind, sun and rain! For example, the TUV-certified H1Z2Z2-K photovoltaic cable can work stably for a long time in an environment of -40℃ to 90℃, with a service life of up to 25 years, which fully matches the use cycle of the photovoltaic system. After the inverter converts the DC power into AC power, it is the turn of the AC photovoltaic cable to "come on stage". It is mainly responsible for transmitting the AC power output from the inverter to the power grid or user end. Compared with DC solar cables, AC solar cables pay more attention to electrical insulation and flame retardant properties. After all, the transmission of AC power has higher safety requirements. Solar cables are exposed to the outdoors all year round, and ultraviolet rays, ozone and humid air are "frequent visitors".

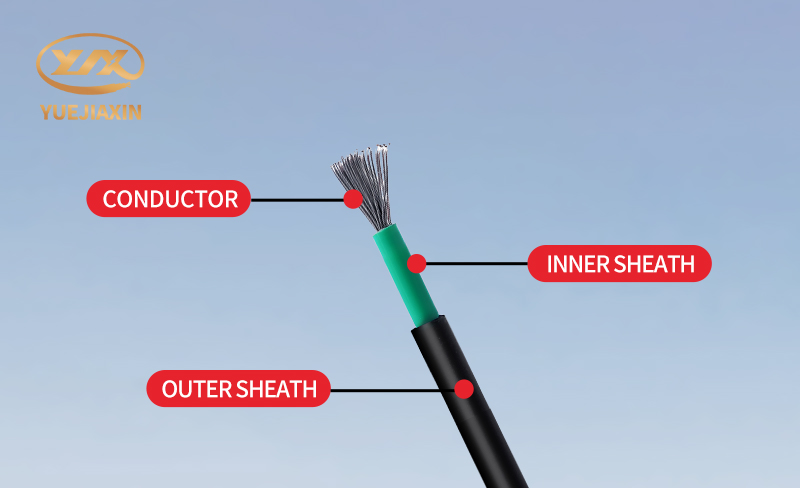

High-quality photovoltaic cables use special polymer materials as insulation layers and sheaths, which can effectively resist UV aging, prevent the cable skin from cracking and hardening, and ensure long-term stable operation. In the hot summer, the surface temperature of the photovoltaic panel can easily exceed 70°C, and the cable must be able to withstand high temperatures without melting or leaking electricity; in the cold winter, the temperature in some areas is as low as -30°C, and the cable must remain soft to ensure that power transmission is not affected. Cables like the H1Z2Z2-K mentioned above can "handle with ease" in extreme temperatures. The conductivity of photovoltaic cables directly affects the efficiency of power transmission, so it usually uses high-purity oxygen-free copper as a conductor, which has low resistance and low loss, and can minimize the waste of electricity during transmission.

When purchasing solar cables, try to choose manufacturers with authoritative certifications, such as TUV certification, CCC certification, etc. Foshan Yuejiaxin Wire and Cable Co., Ltd.'s solar cable products have obtained TUV certification. These certifications are official recognition of the quality and performance of photovoltaic cables. Certified products are more secure in terms of safety and reliability.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable