Cable manufacturers tell you how to choose charging pile cables

In recent years, the development of new energy vehicles has made rapid progress. With the popularization of new energy vehicles, the demand for charging as an important supporting infrastructure is constantly increasing. As the "energy bridge" between charging stations and electric vehicles, the performance of charging cables directly affects the efficiency, safety, and service life of charging stations. So, it is particularly important to choose a suitable charging cable. Today, Yuejiaxin Wire and Cable Company that has been deeply involved in the cable industry for many years, we will share with you how to choose charging cables.

At present, the common charging cables on the market are mainly divided into AC charging cables and DC charging cables, which have significant differences in application scenarios, voltage, power, and other aspects. AC charging cables are mainly used for household and public slow charging stations, characterized by low voltage and low power. DC charging cables are used for fast charging stations because of their high voltage and power, which can quickly replenish a large amount of electricity for electric vehicles and greatly shorten charging time.

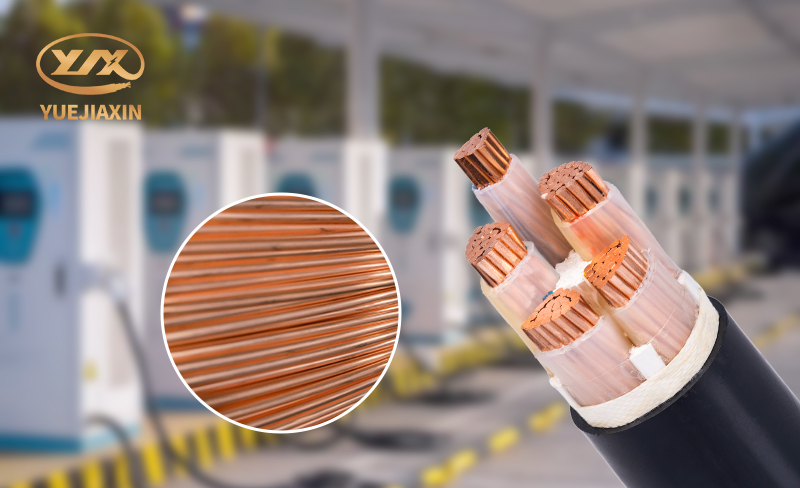

So how should we choose charging cables? Below, Yuejiaxin Company will provide a detailed introduction to the key elements for selecting charging cables from multiple aspects such as material, current carrying capacity, and length. The material of the cable is one of the key factors affecting its performance. Common cable materials include copper wire, aluminum wire, and copper aluminum hybrid wire. Copper wire has excellent conductivity and low resistance, which can effectively reduce the loss of electrical energy during transmission and improve charging efficiency. Moreover, copper wire also has good corrosion resistance, and can work stably for a long time even in harsh environments such as humidity, acidity, and alkalinity, with a long service life. The length of the cable also needs to be determined according to the actual usage scenario, not the longer the better. Generally speaking, a length of 3-5 meters for charging station cables is suitable. This length can meet the connection needs between vehicles and charging stations in most cases, without causing excessive energy loss due to being too long. Charging cables are often subjected to external forces such as bending and stretching in daily use, and may also be exposed to high temperature environments, so they must have good wear resistance and high temperature resistance. Insulation material is also crucial for charging cables. It is like putting a layer of "protective clothing" on the cable, which can effectively prevent current leakage and ensure the personal safety of users. High quality insulation materials not only need to have good insulation performance, but also need to have characteristics such as high temperature resistance and aging resistance. High temperature resistant insulation materials can maintain stable performance in high-temperature environments and will not experience a decrease in insulation performance due to temperature rise; Aging resistant insulation materials can extend the service life of cables and reduce safety hazards caused by aging.

Choosing a charging cable is not a small matter, it requires us to comprehensively consider multiple factors such as material, current carrying capacity, length, wear resistance, high temperature resistance, cross-sectional area, insulation material, and certification standards. Only by selecting the right charging cable can we ensure that the charging process of electric vehicles is both safe and efficient, making new energy travel more worry free. I hope that today's sharing from Yuejiaxin Wire and Cable Company can help everyone avoid confusion when choosing charging cables.