Mineral-selected cables for high-rise buildings strengthen the fire protection power supply safety line.

In our daily lives, we cannot live without electricity. Whether it's household appliances or electronic devices in the office, all require cables to transmit power. Among the many types of cables, which one is best for you? Is it a regular plastic-insulated cable or a mineral-insulated cable with special properties? What are the differences in performance, safety, and lifespan between different cables? Today, let's take a closer look at mineral-insulated cables.

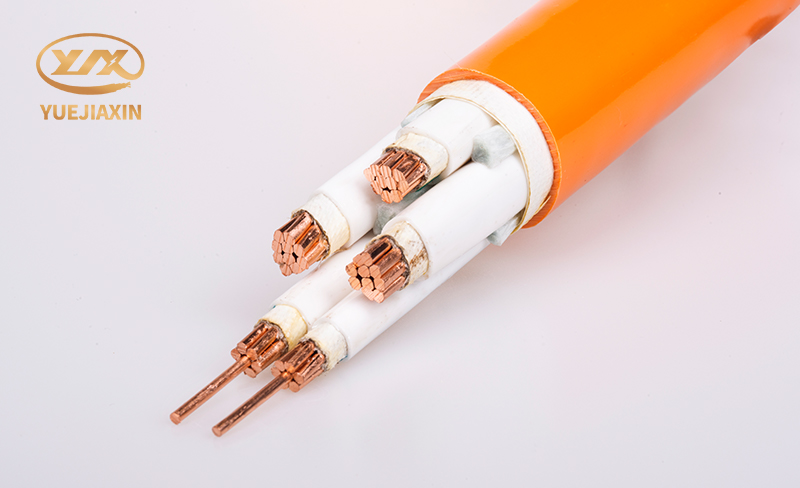

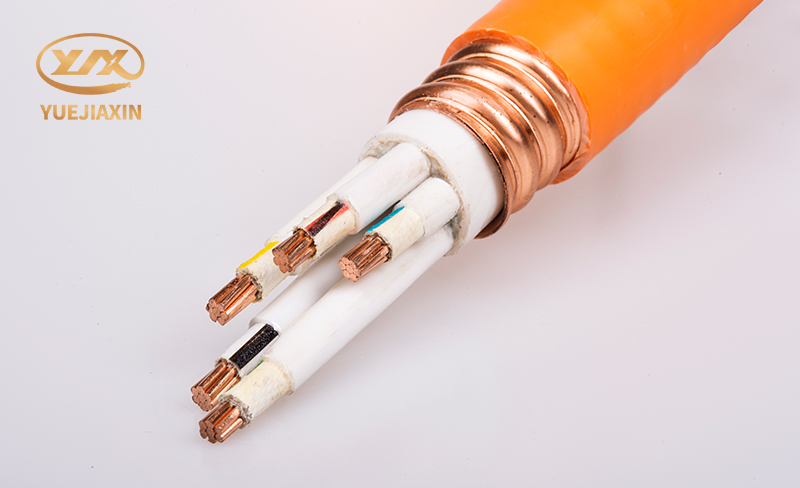

Mineral-insulated cables, also known as mineral-insulated cables or mineral fire-resistant cables in China, are cables composed of a copper core, mineral insulation materials, and a copper or other metal sheath. Their structure is compact. From the inside out, the copper core acts as the current carrier, possessing excellent conductivity; the middle mineral insulation material, such as magnesium oxide, effectively prevents current leakage, ensuring the cable's insulation performance, and is also heat-resistant and non-combustible; the outermost copper or other metal sheath not only provides mechanical protection but also serves as a grounding conductor, while also possessing advantages such as waterproofing, explosion-proofing, and corrosion resistance. Currently, mineral-insulated cables can be divided into rigid and flexible types according to their structural characteristics. The "rigidity" of rigid mineral-insulated cables is reflected in their resistance to bending and their relatively hard cable body, while flexible mineral-insulated cables are relatively easier to bend and are suitable for various cable laying environments, but they are slightly inferior in terms of impact resistance.

What are the differences between mineral-insulated cables and ordinary cables? Ordinary cables typically use organic insulation materials, such as polyvinyl chloride (PVC) and cross-linked polyethylene (XLPE). In a fire, these organic insulation materials melt and burn rapidly at temperatures of 300℃-500℃, not only failing to ensure the normal operation of the circuit but also releasing large amounts of smoke and harmful gases. These gases pose a significant threat to human health and severely hinder rescue efforts at the fire scene. Mineral-insulated cables, on the other hand, use mineral materials for their insulation layer, such as magnesium oxide. These materials have extremely high melting points and are non-combustible and do not support combustion. In a fire, even when facing flames at temperatures of 950℃-1000℃, mineral-insulated cables can maintain the integrity of the circuit and continue to provide normal power, buying valuable time for fire rescue and evacuation. Furthermore, because they do not contain organic materials, they do not produce smoke or toxic gases when burning, greatly reducing secondary hazards during a fire. During long-term use, ordinary cables are susceptible to overloads and short circuits, causing a sharp increase in current and a rapid rise in cable temperature. When the temperature exceeds the insulation material's withstand limit, a fire can easily occur. Furthermore, the insulation material of ordinary cables gradually loses its insulating properties at high temperatures, further exacerbating the fire risk. Mineral-insulated cables, on the other hand, possess excellent fire resistance. Their metallic sheath and mineral insulation effectively block heat transfer, allowing the cable to maintain good electrical performance even in high-temperature environments. Even under overload or short-circuit conditions, mineral-insulated cables can withstand large currents and high temperatures without easily breaking down or igniting, thus preventing fires caused by cable faults and becoming a reliable line of defense for the safe operation of power systems.

Mineral-insulated cables, as a type of high-performance cable, have demonstrated significant advantages in the field of power transmission due to their excellent fire resistance, fire-resistant properties, durability, safety, and wide range of applications.