Aluminum Alloy Cables vs. Copper Core Cables: Performance Comparison + Comprehensive Overview of Applicable Scenarios

In the vast network of power transmission, cables are the unsung heroes working behind the scenes. They bear the crucial responsibility of transmitting electrical energy from power plants to homes, factories, businesses, and commercial centers, serving as an indispensable "lifeline" of modern society. Among the many types of cables, aluminum alloy cables and copper core cables, with their respective unique advantages, have become the two main players in the field of power transmission.

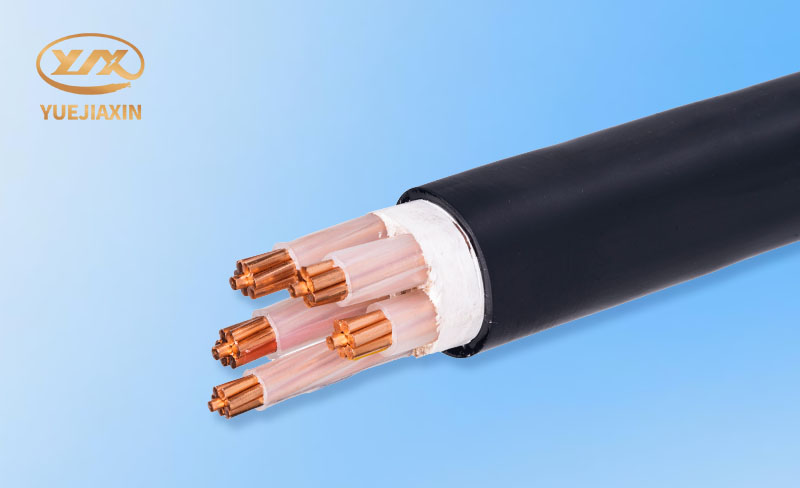

Let's first look at aluminum alloy cables. The conductor of an aluminum alloy cable is made of aluminum alloy material. It's not simply pure aluminum, but rather pure aluminum with various alloying elements added, such as copper, iron, magnesium, silicon, and zinc. Through special processing techniques such as melting, extrusion, and annealing, the physical and chemical properties of the aluminum are optimized. The addition of these alloying elements is like giving the aluminum "superpowers," allowing it to maintain its advantages of light weight and low cost while overcoming the shortcomings of pure aluminum cables, such as poor conductivity and low mechanical strength. It possesses superior conductivity, mechanical strength, and corrosion resistance. Now let's talk about copper core cables. They are the "veterans" of the cable industry, with a long history and wide application. The conductor of a copper core cable is made of high-purity oxygen-free copper or electrolytic copper. Copper has excellent conductivity, being one of the best conductive metals in nature. This means that copper core cables have low energy loss and high transmission efficiency during power transmission, like a smooth highway that allows current to reach its destination quickly and stably.

In the competition of conductivity, copper core cables, thanks to the high conductivity of copper, are the "highways" for current. At the same cross-sectional area, the resistance of aluminum alloy cables is higher than that of copper core cables, resulting in greater energy loss.

In terms of mechanical properties, copper core cables have high tensile strength and can withstand significant pulling forces. In power transmission lines requiring long-distance overhead installation or traversing complex terrain, copper core cables are better able to resist external tensile forces, ensuring the safe and stable operation of the line and preventing breakage due to stress. Furthermore, copper core cables are highly flexible and have excellent bending resistance. When wiring inside buildings, they can easily be bent at various angles, facilitating construction. Although aluminum alloy cables have relatively lower tensile strength, their mechanical properties are improved through alloying. In applications requiring significant cable bending, aluminum alloy cables can be installed more easily.

Different application scenarios have different emphasis on cable performance, which determines the respective strengths and applications of aluminum alloy and copper core cables.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable