Mineral cables - the perfect symbiosis of safety and quality

Today, the wire and cable manufacturer will introduce a mineral cable to you, which can be called the "special forces" in the cable industry, because it can turn the tide at a critical moment and protect our lives and property safety! Mineral cable sounds full of technology and mystery. What exactly is it made of? The following is a detailed introduction by the wire and cable manufacturer. Mineral cable is mainly composed of the following key parts:

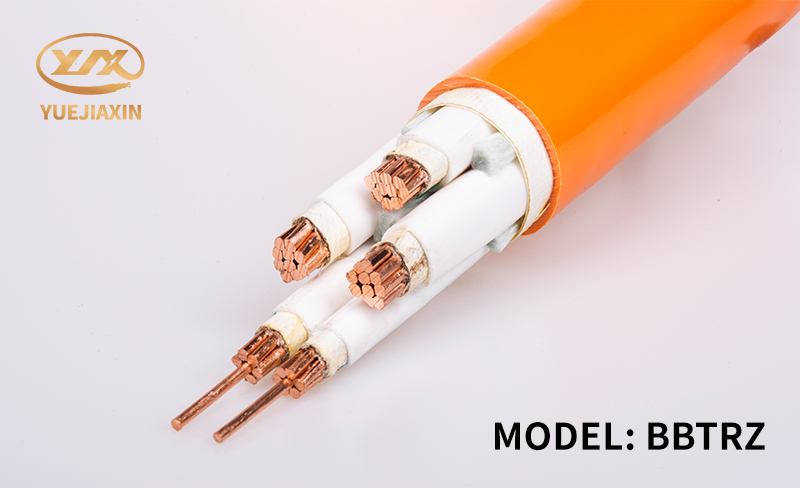

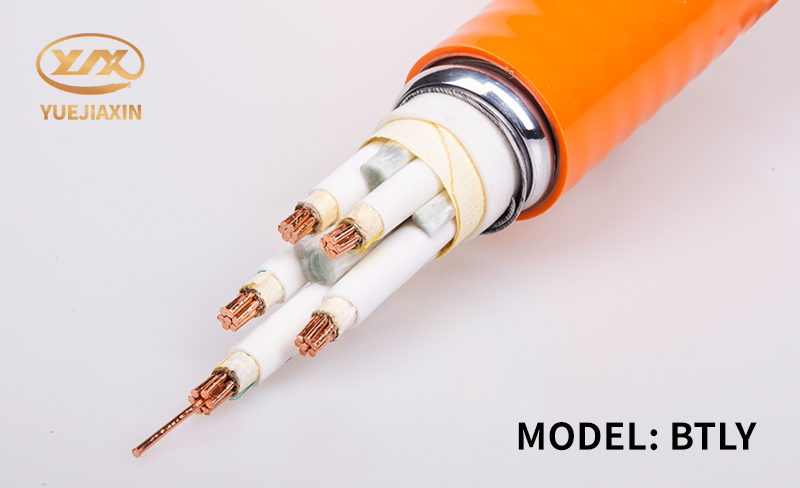

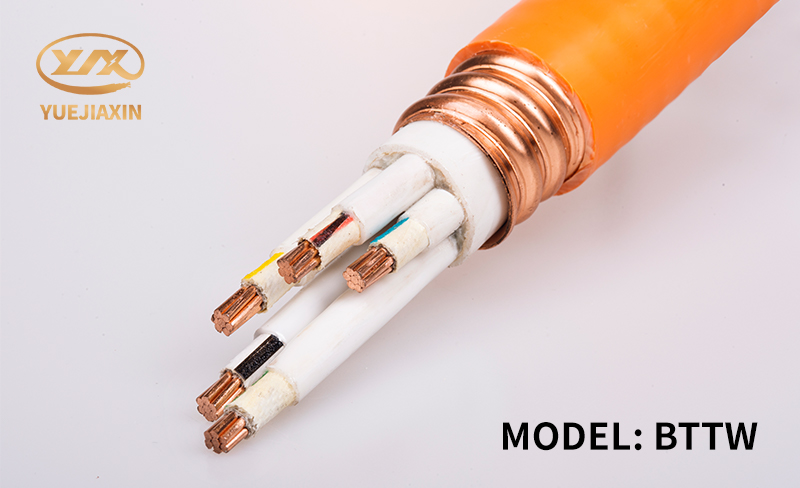

First, the metal copper conductor with high conductivity. As the core of the cable, the conductor is like the blood vessels of the human body, and it undertakes the important mission of transmitting electrical energy. Copper has good conductivity and can efficiently transmit electrical energy to various places where it is needed, reduce energy loss, and ensure the stability and efficiency of power transmission. Then there is the inorganic mineral insulation material that is resistant to high temperature and does not burn. This layer of insulation material is like putting a layer of fireproof armor on the cable. It is composed of inorganic minerals with an extremely high melting point. It will not burn or support combustion. It can maintain stable performance in high temperature environments, effectively isolate current, and prevent dangerous situations such as leakage and short circuit. The low-smoke, non-toxic and corrosion-resistant plastic outer sheath, which is the outermost protective shell of the cable, not only has good corrosion resistance, can resist the erosion of various chemical substances and extend the service life of the cable; but also does not produce thick smoke and toxic gases when burning, avoiding harm to the human body, and providing a strong guarantee for fire safety. It is these special material combinations that give mineral cables excellent performance, making them an ideal choice in many important fields.

Next, the wire and cable manufacturers will explain in detail the excellent performance of mineral cables from the three key aspects of fire prevention, current carrying and durability.

Once a fire occurs, ordinary cables are often vulnerable. Their insulation layers are mostly made of organic materials such as plastics, which are extremely easy to burn at high temperatures. Not only will they quickly lose their power transmission capacity, but they will also become accomplices in the spread of fire, releasing a large amount of toxic and harmful gases, posing a great threat to the safety of personnel. Mineral cables are completely different. Their copper conductors and inorganic mineral insulation materials will not burn themselves, let alone support combustion. Relevant standards stipulate that mineral cables can continuously and stably supply power for 3 hours in high-temperature flames of 950℃-1000℃. This means that when a fire occurs, it can provide reliable power support for key systems such as fire-fighting equipment and emergency lighting, ensure the smooth progress of fire-fighting and rescue work, and buy precious time for personnel evacuation and fire-fighting and rescue. Even at temperatures close to the melting point of copper at 1083℃, mineral cables can still work. This powerful fire-proof performance is beyond the reach of ordinary cables.

In the race of power transmission, mineral cables are like a "sprinter" running at lightning speed. Its normal operating temperature can easily reach 250°C, thanks to the excellent performance of its inorganic mineral insulation material, which can maintain good insulation and stability at high temperatures. Compared with ordinary cables, mineral cables have obvious advantages in interception capacity.

In addition to its excellent fireproof and current-carrying performance, mineral cables are also a proven "iron warrior" with amazing durability and wide adaptability. The seamless metal sheath and tightly compacted insulation material of mineral cables give them excellent waterproof performance. Even if they are completely submerged in water, they can still work normally and provide stable power for underwater equipment. This feature allows them to be used in submarine cables, underwater engineering and other fields. In contrast, ordinary cables are prone to short circuit failures and power outages once they are flooded.

With many excellent performances, mineral cables play an important role in every corner of our lives and have become "invisible guards" to ensure safe and stable operation in various fields. With the continuous development of cities, high-rise buildings have sprung up like mushrooms after rain. These high-rise buildings are tall, densely populated, and have many electrical equipment. Once a fire occurs, the consequences are disastrous. The fireproof, explosion-proof, high-temperature resistant, and corrosion-resistant properties of mineral cables can ensure that in emergency situations such as fires, the power supply of key systems such as fire-fighting equipment, elevators, and emergency lighting is stable and reliable, creating favorable conditions for personnel evacuation and fire rescue.

Mineral cable, like a bright star, shines with unique light in the sky of power transmission. With its excellent performance, wide application and broad development prospects, it brings more safety and convenience to our lives.