Do you know the advantages of rubber cables?.

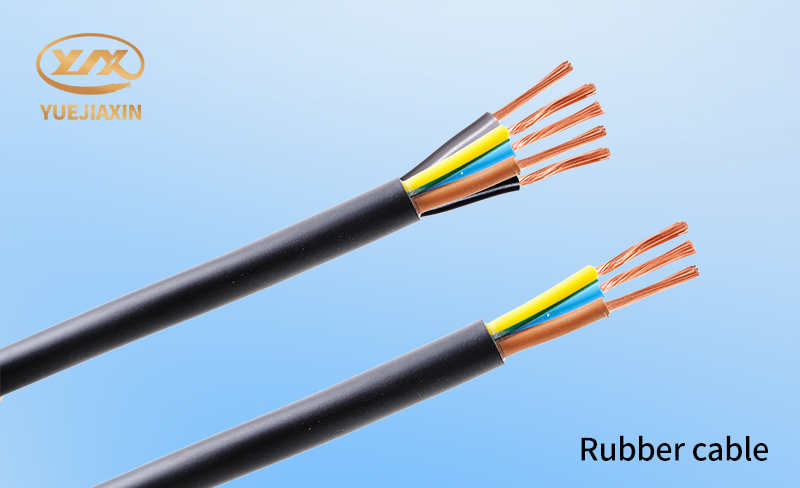

In our daily lives and various construction projects, rubber cables are like silent heroes, constantly playing a critical role, yet often overlooked. When you pass by a bustling construction site, tower cranes, elevators, and other large-scale machinery are operating busily, relying on rubber cables to provide them with stable power. Their high flexibility allows them to flexibly follow the equipment, excelling both on the ground and in overhead operations. Their corrosion resistance and moisture resistance ensure safety and progress at dusty and humid construction sites.

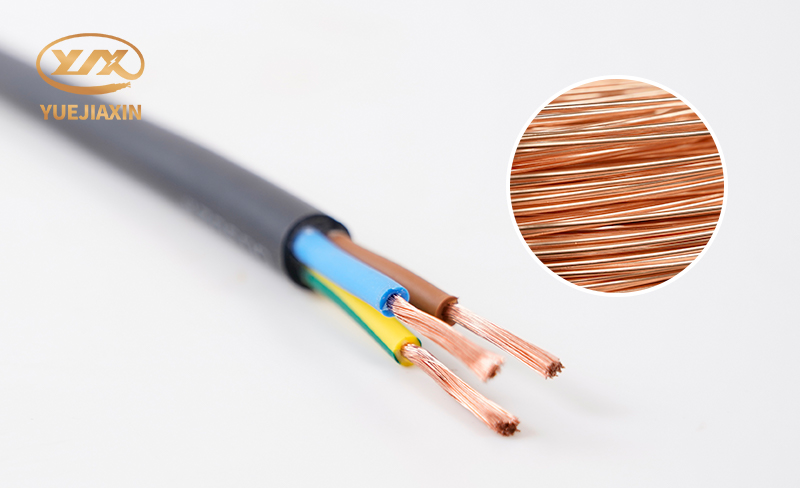

Rubber cables are exceptionally flexible, primarily due to their rubber material and unique structural design. Rubber inherently possesses excellent elasticity, allowing them to deform significantly under stress without breaking. Structurally, rubber cables are typically constructed from multiple strands of fine copper wire twisted together. This twisting method further enhances the cable's flexibility, allowing it to bend and twist like noodles. Insulation performance is a key indicator of cable quality, and rubber cables excel in this regard. Rubber is an excellent insulating material with a tight molecular structure. Electrons are bound around their respective atoms and find it difficult to move freely, thus effectively preventing current leakage.

Whether in the scorching heat of deserts, the biting cold of polar regions, or coastal areas subjected to constant wind and rain, rubber cables endure and operate reliably. This is because the material selection and processing of rubber cables fully consider the impact of various harsh climates. The rubber material used is specially formulated and processed to provide excellent resistance to UV rays, oxidation, and high and low temperatures. Chemical plants produce large amounts of highly corrosive chemicals such as acids and alkalis during production. If ordinary cables come into contact with these substances, they will quickly corrode and damage them, causing power transmission interruptions and disrupting normal production.

When selecting rubber cables, the first thing to do is to determine the current load. Based on the power of the equipment using them, accurately calculate the required current value and determine the appropriate cable conductor cross-sectional area. The operating environment is also a key factor in selecting a cable. The installation method is also crucial.

When using rubber cables, overloading must be strictly avoided. Overloading can cause cable temperatures to rise sharply, accelerating insulation aging, shortening cable life, and even causing fires. Regular inspections are crucial to ensuring the proper operation of rubber cables. With continuous advancements in materials science and manufacturing processes, the performance of rubber cables will continue to improve, and more rubber cables with specialized properties may emerge in the future.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable