Comparison between aluminum alloy solar cables and copper core solar cables

At present, the mainstream solar cables on the market are mainly aluminum alloy solar cables and copper core solar cables. These two cables are like two equally strong players, each with its own advantages. They have obvious differences in conductivity, mechanical properties, cost, corrosion resistance, etc., and these differences directly determine their application performance in different scenarios.

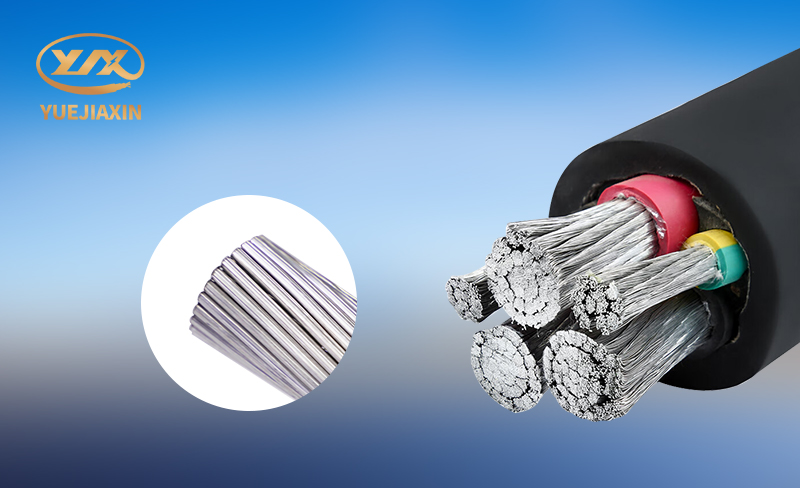

The primary advantage of aluminum alloy cables is reflected in cost and weight. Because aluminum has abundant reserves in the earth's crust, its price is more affordable than copper. This can effectively alleviate cost pressure and improve the economic benefits of large-scale photovoltaic power station construction. In terms of weight, the density of aluminum alloy cables is only about one-third of that of copper. In some large-scale photovoltaic power station projects, the use of aluminum alloy cables can reduce transportation costs by about 30% and increase installation efficiency by more than 20%. This not only reduces the transportation burden, but also reduces the difficulty of installation, making the construction process more efficient and convenient.

Aluminum alloy cables also have excellent mechanical properties and corrosion resistance. Moreover, the bending radius of aluminum alloy cables is small, only about half of that of copper core cables, which makes it more flexible during installation and can easily adapt to various complex wiring environments. However, the conductivity of aluminum alloy cables is only 61.8% of that of copper, which is a major flaw in its conductivity. Under the same cross-sectional area, the current carrying capacity and conductivity of aluminum alloy cables are significantly weaker than those of copper core cables. In practical applications, in order to meet the needs of power transmission, it is often necessary to increase the cross-sectional area of aluminum alloy cables. Because aluminum alloys are very easy to oxidize in the air, forming a dense oxide layer, this oxide layer will hinder the conduction of current, affecting the reliability of electrical connections. It is necessary to overcome the insulation properties of the surface oxide layer.

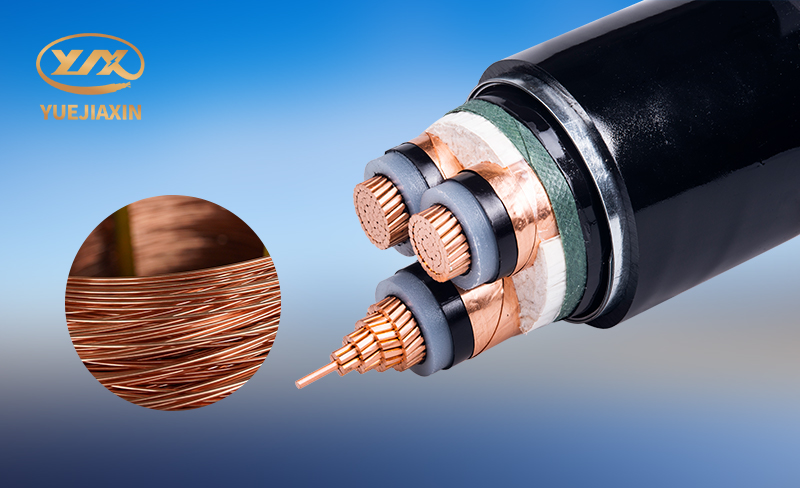

Copper core cables are outstanding in electrical performance, with extremely low resistivity, which makes their conductivity extremely excellent, far superior to aluminum alloy cables. In actual photovoltaic systems, copper core cables can significantly reduce voltage drop and power loss, greatly improving the power generation efficiency of photovoltaic systems. Moreover, copper has good tensile strength and ductility, which makes copper core cables more stable in complex installation environments and long-term operation. The corrosion resistance and oxidation resistance of copper core cables are also outstanding. Copper is not easily oxidized in the air and can form a dense protective film on the surface, effectively preventing further oxidation and corrosion. This gives copper core cables certain advantages in service life and maintenance costs, and can provide longer and more stable operation guarantees for photovoltaic systems.

Although copper core cables have outstanding advantages, their disadvantages in cost and weight cannot be ignored. As an important metal resource, copper is relatively expensive, which leads to high raw material costs for copper core cables. Compared with aluminum alloy cables, the material cost of copper core cables is usually 50% - 80% higher. In the construction of large-scale photovoltaic power stations, the amount of cables used is huge, which further amplifies the cost disadvantage of copper core cables and brings a heavy economic burden to the project. In addition, the high density of copper makes copper core cables much heavier than aluminum alloy cables. This will increase costs and difficulties during transportation and installation.

Aluminum alloy solar cables and copper core photovoltaic cables are like the two ends of a scale, each carrying unique advantages and disadvantages. Aluminum alloy solar cables are favored in large-scale photovoltaic power stations and distributed photovoltaic power generation projects due to their low cost, light weight, and corrosion resistance. They can effectively reduce the initial investment and subsequent maintenance costs of the project. Copper core photovoltaic cables, with their excellent conductivity, mechanical strength, and stability, have become the first choice for high-power transmission and scenarios with strict electrical performance requirements, ensuring efficient and stable transmission of electricity. However, the higher cost, heavier weight, and the risk of price fluctuations caused by resource scarcity make it face certain economic pressure when applied on a large scale.