Small cables contain great knowledge

When going to work, whether driving a car, the complex circuit system in the car, from the start of the engine to the operation of various electronic equipment, cannot be separated from cables; or choosing public transportation, the subway is running on the track, and its operation depends on the powerful power provided by the power supply cable. The signal cable guarantees accurate signal transmission and ensures the safe and efficient operation of the train. In the office, computers, printers, air conditioners and other equipment form an orderly power network through cables to support daily office work. Although cables are not often noticed, they are everywhere and are essential to our lives. So what kind of knowledge do these common cables in life have?

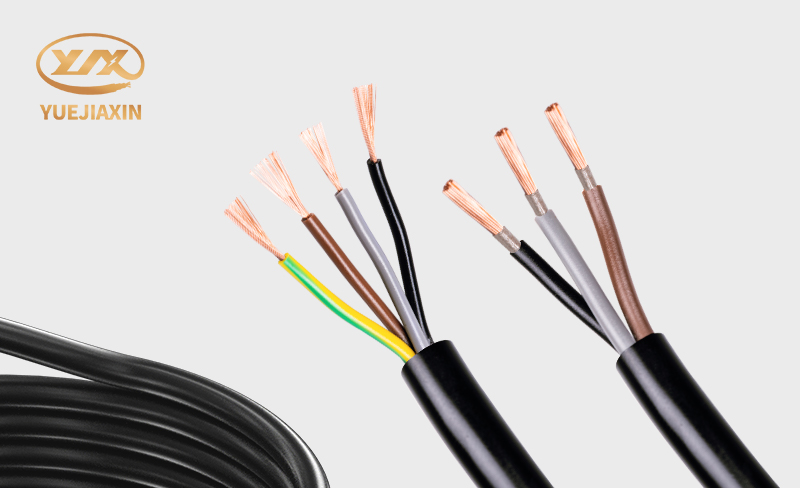

Conductors, as the core of cables, provide an unobstructed channel for electric current. Common conductor materials are copper and aluminum. Copper has strong conductivity and good corrosion resistance, while aluminum is light in weight and low in cost. They are used in different scenarios. In some power transmission scenarios that are more cost-sensitive and have longer transmission distances, aluminum conductors are more advantageous. The insulation layer tightly wraps the conductor to prevent current leakage and avoid short circuits between different conductors. Common insulating materials include polyvinyl chloride (PVC), polyethylene (PE), cross-linked polyethylene (XLPE), etc. In low-voltage environments, PVC is widely used due to its low cost and good insulation performance; in high-voltage power transmission, XLPE has become the preferred material for cable insulation due to its excellent heat resistance and insulation stability. The sheath is the solid armor of the cable, located at the outermost layer, protecting the internal conductor and insulation layer. It can not only resist the impact of external mechanical forces, but also be waterproof, moisture-proof, and chemically resistant, extending the service life of the cable. Like the common polyvinyl chloride sheath, it has high mechanical strength and strong chemical corrosion resistance; in some special environments that require oil resistance and wear resistance, special materials such as chloroprene rubber sheaths are used.

The cable family is huge. According to the purpose, it mainly includes power cables, control cables, communication cables and special cables. Power cables are the main force in transmitting electric energy and are widely used in urban power grids, power plants, industrial and mining enterprises, etc. From low voltage to ultra-high voltage, power cables of different voltage levels undertake different scales of power transmission tasks. Control cables are mainly used in industrial automation control systems to transmit control signals and ensure the precise operation of various equipment. Communication cables are the "information highways" of the information age, used to transmit various communication signals such as voice, data, and images.

Different usage scenarios, like different battlefields, have completely different requirements for cable performance. Only by choosing the right cable can it play a stable role in each scenario.

In household electricity scenarios, low-voltage power cables are usually used, such as common PVC insulated PVC sheathed (VV) cables and cross-linked polyethylene insulated PVC sheathed (YJV) cables. Moreover, the home environment is relatively stable, and the main requirements for cables are good insulation performance, which can ensure the safety of electricity use, and the price is relatively affordable. For ordinary lighting lines, 1.5 square millimeters or 2.5 square millimeters of BV (copper core PVC insulated wire) wire is sufficient; while high-power electrical appliances such as air conditioners and electric water heaters require 4 square millimeters or even 6 square millimeters of wire to ensure that they can withstand larger currents.

In outdoor overhead or underground power transmission scenarios, cables must withstand natural factors such as wind, sun, rain, freezing, and soil corrosion. Overhead cables need to have sufficient mechanical strength to withstand their own weight and wind force, and also have good weather resistance, such as cross-linked polyethylene insulated overhead cables; buried cables should focus on waterproofing, moisture-proofing, corrosion resistance, and the ability to withstand soil pressure. YJV22 cross-linked polyethylene insulated steel belt armored PVC sheathed power cable has become a common choice for underground laying due to its sturdy armor layer and corrosion-resistant sheath.

With the rapid development of science and technology, the cable industry is also constantly moving towards a new journey. In the future, superconducting cable technology is expected to achieve greater breakthroughs. Its zero resistance characteristics will greatly reduce the energy loss in power transmission, making long-distance transportation of electricity more efficient, and laying the foundation for building a more powerful smart grid; high-temperature resistant cable technology will continue to upgrade to meet the stringent requirements of more high-temperature industrial scenarios and ensure the stable operation of equipment in extreme environments; flexible cables will be more intelligent and durable, and will be able to show their talents in the fields of smart manufacturing, wearable devices, etc., providing strong support for the development of these emerging industries. Cables, this "behind-the-scenes hero" who silently dedicates himself in our lives, from early morning to night, it consistently ensures the stable transmission of power and signals, supporting the convenience and efficiency of modern life.