How much do you know about weak-current cables (B)

Last time, we introduced some basic knowledge about weak-current cables, including what weak-current cables are and what are the common weak-current cable models. Today, we will continue to give you a deeper understanding of weak-current cables. Let’s first take a look at the laying process of weak-current cables. Cable laying is the most important item in concealed engineering. The quality of cable laying directly affects the quality of the project and the amount of maintenance of the project. Faults caused by cable laying are generally difficult to find and eliminate, and the cost of solving them is high. Therefore, cable laying is the focus of our civil engineering work and the focus of inspection and assessment.

Before laying out the power and signal cables, the insulation of the cables must be measured. The insulation resistance of the cables is usually clearly marked on the surface of the cables, and the test value must be greater than this value. During the laying of the cables, the torsion of the cables during coiling must be removed. When laying out the cables, the cables are usually rotated while pulling the cables to release the torsion. During the laying of the cables, a laying record sheet must be prepared to facilitate future searches and archiving of information. The cable laying record sheet must record the type of cable, the number of meters at the starting end of the cable, the number of meters at the end end, the direction of the point, and other information.

Precautions for laying weak-current cables:

(1) For bridges with separate strong and weak-current cables, the cables must be laid separately when laying out. The power cables should be placed on the wider side, and the video cables, control cables, and signal cables should be placed on the narrow side.

(2) Cables should be laid in a single layer, kept horizontal, and not crossed. The bending radius of the cable with the maximum cross section should be used for construction at the bend (turn along the outside of the trough box).

(3) Before laying out the cables in the cable well, the cover must be lifted every 20 meters. After ventilation for 1 day, the cables can be threaded into the well.

(4) Strong and weak-current cables must be laid separately in the cable well, with high-voltage cables at the bottom and low-voltage cables at the top.

(5) Direct burial is a wiring method for burying armored cables directly underground. Before laying armored cables, debris in the trench must be removed to ensure that the bottom of the trench is sand or fine soil. The cable should have an appropriate amount of serpentine bends when laid in the trench, and appropriate margins should be left at both ends of the cable, the middle joint, the cable well, the pipe crossing, and the vertical position difference. Insulation shaking test or voltage withstand test must be carried out before and after cable laying.

In the next passage, we will continue to take you to a deeper understanding of the application scenarios of weak-current cables.

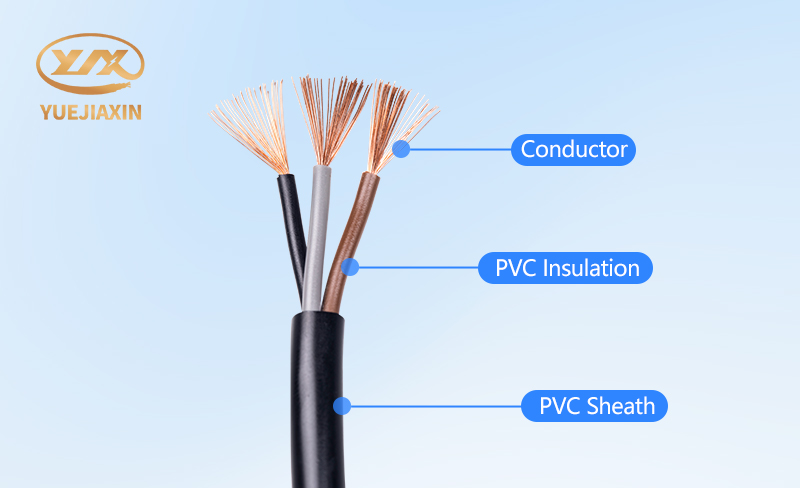

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable