Economical aluminum wire, unlimited conveying possibilities

In daily life, we rely on electricity everywhere. Whether it is lighting up the room or running various electrical appliances, wires are indispensable. Among the many types of wires, although aluminum wires are not as well-known as copper core wires, they also play an important role in many fields.

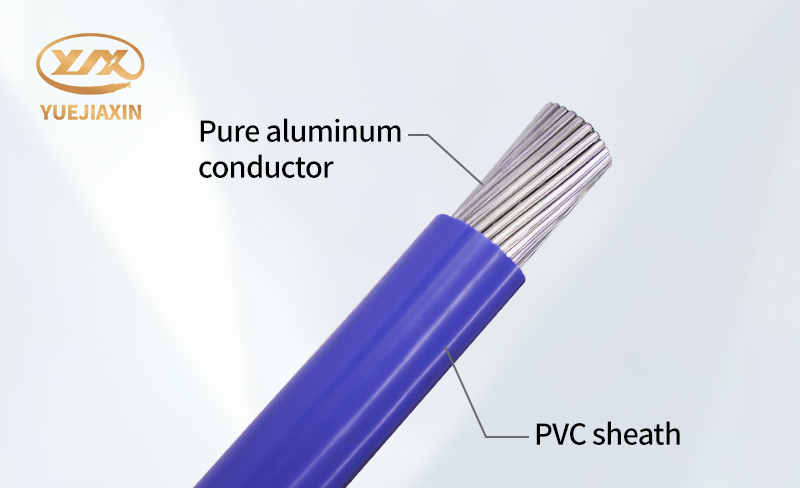

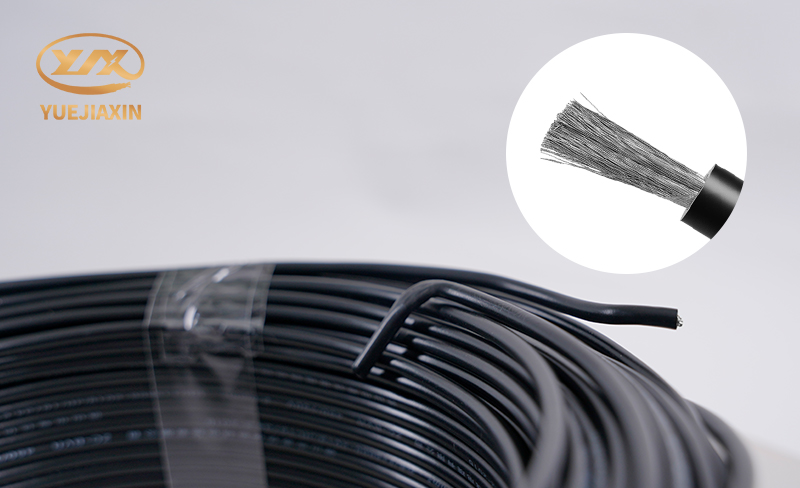

Aluminum wires are wires that use aluminum as a conductor material. It is mainly composed of aluminum conductors, insulation layers, and possible sheath layers. The aluminum conductor is responsible for the transmission of current, the insulation layer plays a role in isolating the current and ensuring safety, and the sheath layer can further protect the internal structure and enhance the durability and protection performance of the wire.

In the market, there are many common models of aluminum wires, each of which has its specific uses and applicable scenarios. For example, BLV is an aluminum core polyvinyl chloride insulated wire. Its insulation material is polyvinyl chloride, which has good insulation performance and certain corrosion resistance. It is relatively affordable and is often used in some low-voltage power transmission and indoor wiring scenarios that are more cost-sensitive, such as lighting lines in ordinary houses and simple electrical equipment connections. YJLV is an aluminum cross-linked polyethylene insulated polyvinyl chloride sheathed power cable. The cross-linked polyethylene insulation material gives it better electrical performance and heat resistance, and the polyvinyl chloride sheath provides additional protection. Therefore, it is often used in medium and low voltage power transmission systems, and is more common in power wiring in some factories, shopping malls and other places. There is also a VLV type aluminum core polyvinyl chloride insulated polyvinyl chloride sheathed power cable, which also uses polyvinyl chloride as insulation and sheath materials, has good insulation performance and corrosion resistance, and is often used in indoor wiring, lighting lines and power lines.

Aluminum resources are abundant and the price is relatively low compared to copper. For some large-scale engineering projects, if aluminum wires are used, a considerable amount of money can be saved in the wire procurement process. This is of great significance for controlling the project budget. Aluminum wire has good corrosion resistance. Aluminum can quickly react with oxygen in the air to form a dense aluminum oxide film on its surface. This film is like a solid armor that can effectively prevent aluminum from further oxidation and corrosion.

However, aluminum wires age relatively quickly during use, especially in harsh environments such as high temperature and humidity. Moreover, the mechanical strength of aluminum wires is poor, which makes aluminum wires more likely to break or be damaged when stretched or bent by external forces.

Despite the relatively poor mechanical properties, aluminum wires are widely used in many fields due to their own characteristics. For example, it is a common choice in power transmission and distribution systems. Especially in long-distance power transmission, the advantages of aluminum wires in terms of light weight can be fully utilized, which can reduce the load of supporting structures such as poles and towers and reduce construction costs. Aluminum wires also play a role in new energy systems. Aluminum cables are often used in solar photovoltaic power generation systems. Photovoltaic power stations are generally built outdoors, and the corrosion resistance of aluminum cables can adapt to the complex outdoor environment and ensure the stability of power transmission.

As a member of the wire family, aluminum wire has unique characteristics. It is affordable, lightweight, and corrosion-resistant, and plays an important role in many fields such as power transmission and distribution, building electrical, transportation, and new energy systems. However, it also has disadvantages such as poor conductivity, easy aging, and weak mechanical strength. I hope that through today's introduction, everyone will have a deeper understanding of aluminum wires, and in future work or life scenarios involving wires, they can make wise choices based on actual needs.