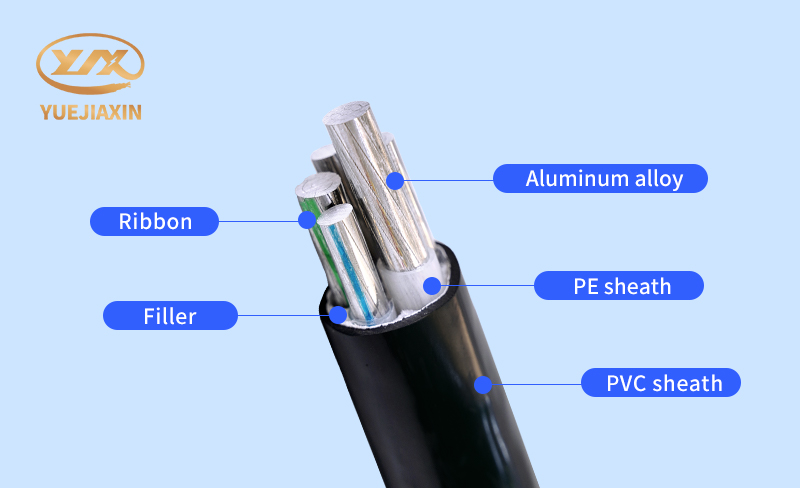

Aluminum alloy cables support factory projects, adding new momentum to green power transmission.

In an era where the "dual-carbon" goal is driving a new trend of green development and the new infrastructure wave is sweeping across the land, traditional copper cables, the "veteran" of power transmission, are gradually showing signs of fatigue. High costs and excessive weight are like heavy shackles, limiting their progress in the new era. At this critical juncture, aluminum alloy cables, with their lightweight design and superior performance, have emerged as a powerful force in the power transmission field, breaking through and entering the public eye.

This new type of cable, a culmination of cutting-edge materials science and engineering innovation, is far more than just a simple material replacement. It is a "new favorite in the power industry," born to meet the increasingly diverse needs of new energy, infrastructure, and industrial sectors. With its exceptional cost-effectiveness and strong environmental adaptability, it has become a "must-have" choice for many projects. What magical power does it possess? Let's explore the secrets of aluminum alloy cables together.

In the cost accounting of power transmission, aluminum alloy cables are truly experts at cost-effectiveness. For the same current carrying capacity, aluminum alloy cables cost 30% to 50% less than copper cables. Beyond procurement costs, the lightweight nature of aluminum alloy cables brings significant cost reductions and efficiency improvements in transportation and installation. Weighing only 50% to 60% of copper cables, this means fewer transport vehicles are needed, resulting in a 40% reduction in transportation costs. On the installation site, workers can move aluminum alloy cables much more easily, eliminating the need for large lifting equipment and increasing labor efficiency by over 30%. In some complex mountainous power construction projects, copper cables are difficult to transport and lay due to their weight, while aluminum alloy cables, with their lightweight design, can be quickly transported to the designated location and installed, greatly shortening the construction cycle and creating conditions for the project to be energized as soon as possible.

In terms of performance, aluminum alloy cables excel in creep resistance and high flexibility. Their flexibility is also outstanding, with a bending radius of only 7 times the outer diameter, compared to 10-20 times the outer diameter for copper cables. Aluminum alloy cables also demonstrate superior corrosion resistance and high-temperature resistance. The naturally formed dense oxide film on the surface of aluminum alloy acts like a robust "armor," effectively resisting the erosion of acids, alkalis, and other chemicals. During production, aluminum alloy cables utilize a low-smoke, halogen-free sheath, a design that is crucial in the event of a fire. When burning, it does not release toxic gases such as hydrogen chloride, reducing secondary injuries at the fire scene and creating a safer environment for escape and fire rescue.

From an "economical alternative" to copper cables to a "core component" supporting new energy and new infrastructure, the rise of aluminum alloy cables represents not only a material upgrade but also an efficiency revolution in the field of power transmission. Whether in engineering procurement or industry investment, understanding its "versatile applications" and "technological potential" is crucial to gaining a competitive edge in the green infrastructure wave.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable