Aluminum alloy cables safely transmit every kilowatt-hour of electricity.

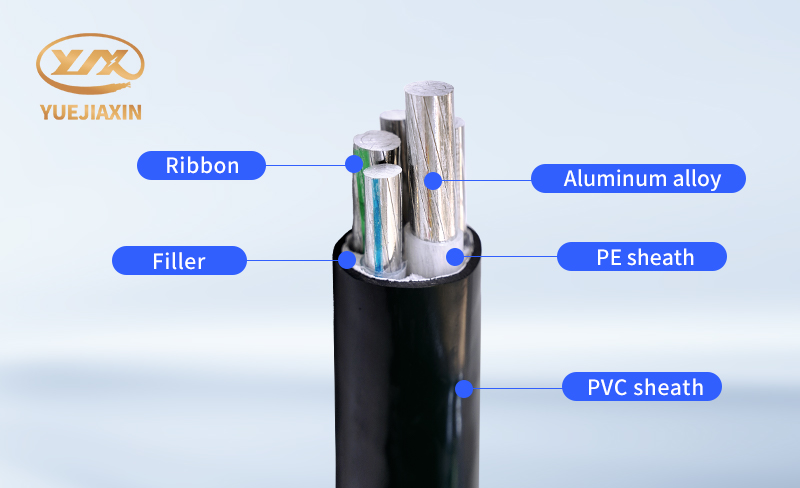

Power transmission is the lifeline of modern society. Today, cable manufacturers will introduce aluminum alloy cables. Aluminum alloy cables are a new type of cable made from aluminum alloy as the conductive material. Aluminum alloys utilize a unique alloying formula and advanced processing techniques. By adding alloying elements such as copper, iron, magnesium, silicon, zinc, and boron to electrical aluminum, they significantly enhance the cable's overall performance. Aluminum alloy cables hold a vital position in the power sector, enjoying a wide range of applications.

Aluminum alloy cables stand out from other cables due to their exceptional safety performance, a key element in ensuring safe power transmission. They offer strong creep resistance. Aluminum alloy cables utilize a special annealing process and incorporate rare earth elements and iron into the conductor to achieve high creep resistance. Even under current overload conditions, the iron maintains its connection, preventing creep in the aluminum alloy conductor, ensuring stable and secure cable connections. Compared to pure aluminum, aluminum alloy conductors significantly enhance their tensile strength due to the addition of special elements and specialized processing. They also offer enhanced bending performance. While typical copper cables have a bend radius of 10 to 20 times their outer diameter, aluminum alloy cables have a bend radius of only 7 times their outer diameter. This smaller bend radius makes aluminum alloy cables more convenient for corner installation and meets various complex wiring requirements. It also reduces the impact of excessive bending on cable performance, ensuring stable power transmission.

In the field of power transmission, traditional copper and aluminum cables have long dominated. However, the emergence of aluminum alloy cables has brought new solutions to power transmission security, offering significant safety advantages over traditional cables.

With the continuous advancement and innovation of technology, the advantages of aluminum alloy cables in safely transmitting power will become increasingly prominent, and their future development prospects are promising. In the field of new energy, the demand for cables for power stations powered by solar, wind, and other renewable energy sources is increasing. Aluminum alloy cables, with their excellent high-temperature resistance, corrosion resistance, and lightweight design, can ensure stable power transmission from power stations to the grid in harsh natural environments, strongly supporting the widespread use of renewable energy. In the future, with the vigorous development of the new energy industry, the application of aluminum alloy cables in this field will continue to expand, making them a key choice for new energy power transmission.

- PVC-Insulated Cable

- 450/750V BV Single- Core Cu/PVC Cable

- 450/750V BVR Single- Core Cu/PVC Cable

- 300/500V Or 450/750V RV Single-Core Cu/PVC Flexible Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible Black Cable

- 300/500V Or 450/750V RVV Multi-Core Cu/PVC/PVC Flexible White Cable

- 300/500V Or 450/750V RVVP Multi-Core Cu/PVC/CWS/PVC Screened Flexible Cable

- 450/750V KVV Multi-Core Cu/PVC/PVC Control Cable

- 450/750V KVV22 Multi-Core Cu/PVC/STA/PVC Armoured Control Cable

- 450/750V KVVP Multi-Core Cu/PVC/CWS/PVC Screened Control Cable

- 450/750V KVVP2-22 Multi-Core Cu/PVC/CTS/STA/PVC Screened Armoured Control Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Single-Core Power Cable

- 0.6/1KV PVC-Insulated PVC-sheathed Multi-Core Power Cable